| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

SET

TOTAL COST

$1660| Model : XC-TM6KW-W | Delivery Port : Jiangmen | delivery Time : 15days | Product Advantages : Well and High Quality Control, Prompt Delivery, New Product, Competitive Prices, Earth-friendly Products, Small Order Acceptable |

| Material : Default |

| Pcs/Carton : N/A | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : N/A | QTY in 20GP : N/A |

|

Condition: |

New |

Place of Origin: |

Guangdong, China (Mainland) |

Brand Name: |

XIECHENG |

|

Use: |

Film Crusher |

Plastic Type: |

PP/PE |

||

|

Shaft Design: |

Single |

Power: |

10HP |

Capacity: |

200~300kg/h |

|

Voltage: |

380V/50Hz/3phase as usual |

Power(W): |

7500 |

Dimension(L*W*H): |

1050*800*1300mm |

|

Weight: |

430kg |

Certification: |

CE |

After-sales Service Provided: |

Overseas third-party support available |

|

Inner fitting: |

Double layer hopper with deadening |

Type: |

environment-friendly |

color: |

black and white |

|

Shape: |

flat type |

life time: |

more than 5 years |

suit for: |

plastic/soft pipe |

|

Packaging Details: |

Standard wooden case as usual |

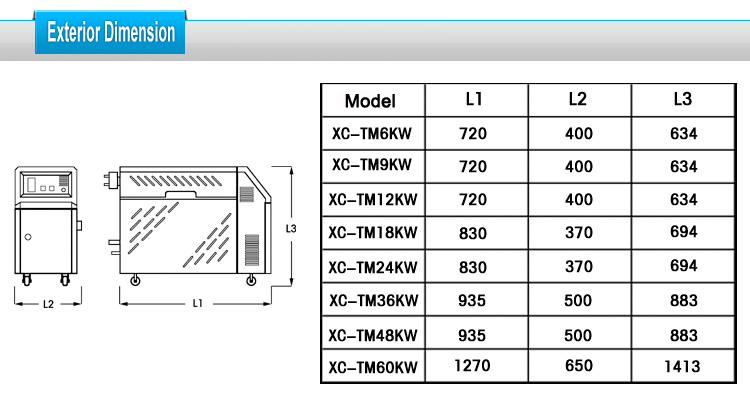

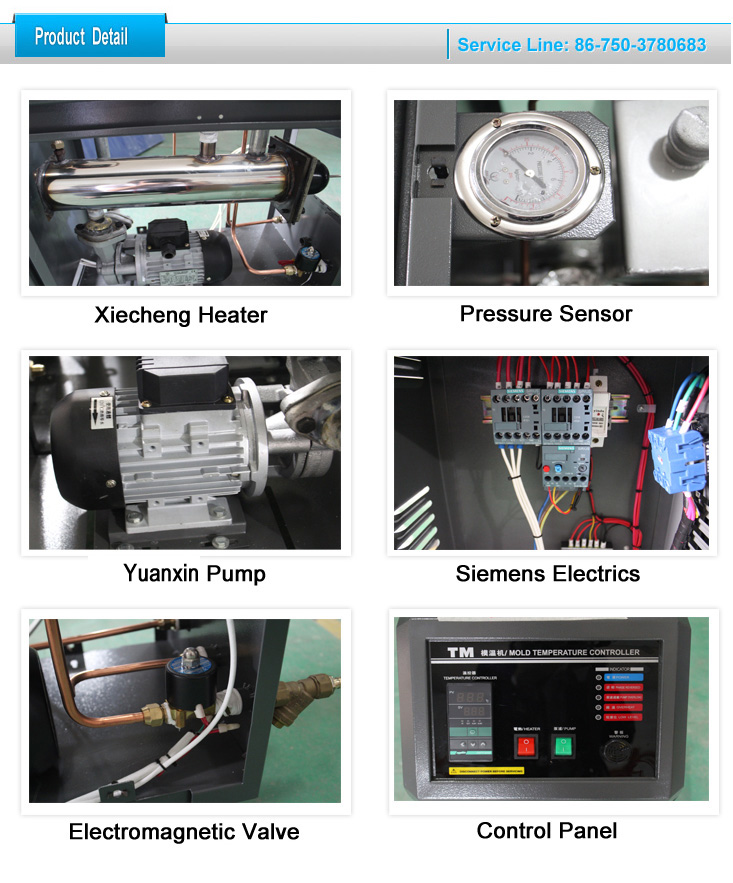

XIECHENG 12KW Oil Mold Temperature Controller Machine for Plastic Industry

XIECHENG 6KW Water Mold Temperature Controller Machine for Plastic Industry

1, PID adopted to control the temperature. Controling error within ±0.5°C.Keeping long time constant temperature, high efficiency and energy saving.

2, Six protective measures: alarm for thermo- couple open circuit, phase fault protect, pump protect, overheat protect, oil shortage protect.

3, Dual digital display shows the actual temperature and the seat temperature.

4, Microcomputer chip control panel with light-touch switch to start the machine with one press Visual and easy to operate, easy to maintain

5, Stainless steel tank without leakage and durable

6, Circumfluence type is able to recollect the diathermanous oil easily and rapidly

7, Exquisite appearance and small in size

Application:

Reaction kettles, extrusion forming equipment, rubber forming machinery, cast film production lines, cable extrusion production lines, the dies for precise plastic molding, the dies for the compression casting of magnesium/aluminum/zinc alloy, roller pressing applied in rubber/plastic and leather industries, crude oil heating of the oil sinks on tankships, paper making industry, bottle blowing, and so on.

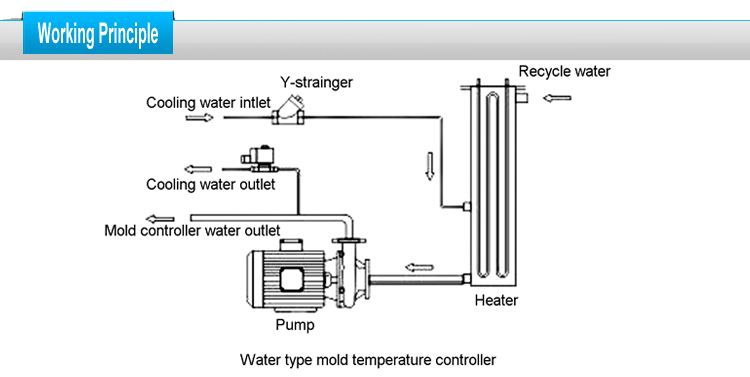

This Mold Temperature Control System has been designed to maintain a constant temperature, using water or oil as medium. Mold temperature controller is used to control temperature in various industrial fields.

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.