Tray Cabinet Dryers for simultaneous drying of different kinds of polymers in or for drying materials for trial moulding

BTCD Series

Tray Cabinet Dryers

General Description

BTCD series of cabinet dryer are mostly used for simultaneous drying of different kinds of polymers in small quantities or for drying materials for trial moulding. They can also be applied in electronic engineering electroplating, pharmacy, paint baking, printing industries, etc. for preheating or drying related products.

BTCD-9

BTCD-9  BTCD-20

BTCD-20

Features

1) Accurate P.I.D. temperature control to achieve an even drying effect.

2) Air-proofed insulative door can maintain temperature constantly inside to reduce energy consumption.

3) Stainless steel tray and liner bring no contamination to materials.

4) Optimal design for ease of maintenance and service.

5) Unique design of adjustable air inlet and exhaust.

6) 24 hours timer, easy to operate.

7) Overheat protector can prevent excessively drying.

8) Motor overload relay.

9) Visible alarm to indicate troubles immediately.

10) Tray size and inner dimensions of the dryer can be specified according to requirements.

11) Upon request, it can be built to comply with worldwide electrical safety standard (For example : CE, UL CSA,JIS etc.).

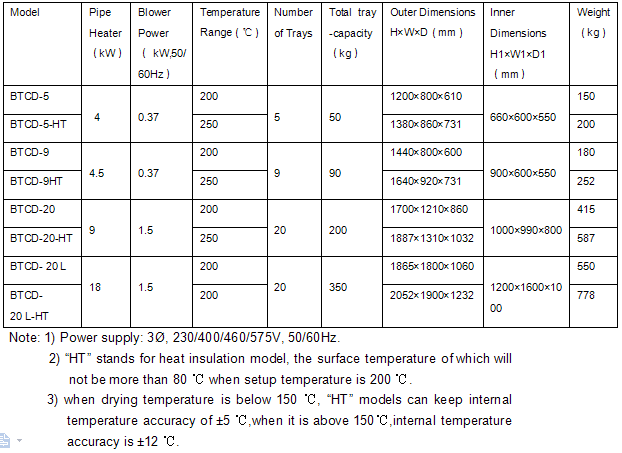

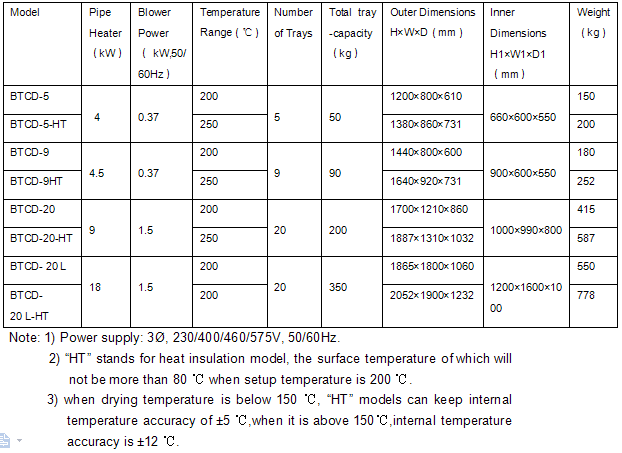

Specifications

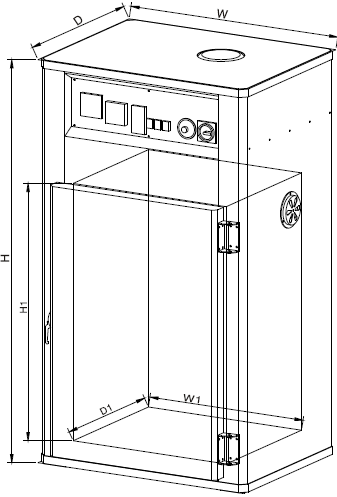

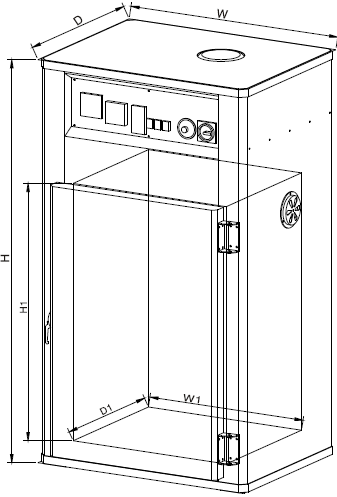

Outline Drawing

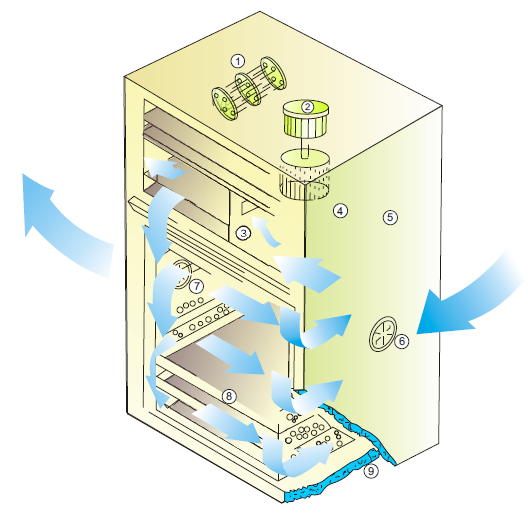

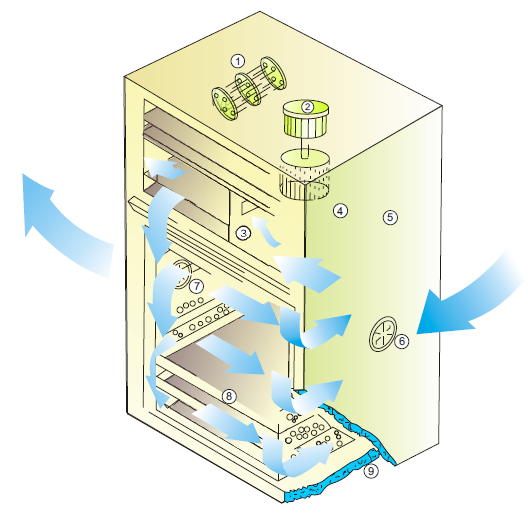

Working Principle

For cabinet dryers, materials to be dried are place on the stainless steel moveable material trays. During operation, process air will flow to heating coil and be heated up to required temperature, then flow through a manifold with evenly scattered holes. Moisture air is set out through air exhaust port. Designed to achieve a uniform drying effect.

1. Heating Coil 2. Air Inlet Blower 3. Air Chamber

4. Multi-vane Impeller 5. Paint-baked Cover 6. Air Inlet

7. Air Exhaust 8. Stainless Steel Tray 9. Heat-resistant Layer

Why choose us?

1.We can make and manufacture products according to customer specific needs.

2.Provide best and professional service for you, please contact with us freely.

3.For more information, please contact us at any time.

4.Stable performance, best price, good quality, good after-sales service.

SBT - Quality First, Always

At SBT, we believe in the business philosopu of "service, quality, honesty and trust". We are grateful for the support of our clients and are committed to continuously develop innovative products to help them in their business. We firmly believe that when our clients succeed, we succeed. Our innovative efforts have seen us attained ISO 9001:2008 and the European CE certification.

At SBT Plastic, we are committed to continuously innovate and improve our products and services.

Hearty service:

1.Before sending the machine, we will test and adjust, so you can use directly when you get it.

2.Operating video & instruction will be sent to clients, to help them better use the machine.

3.Any problems occur while using, professional advice will be given by us.

4.All kinds of frequently used parts are supplied from us all the year round.

Service before sale:

Customer oriented:Best developed, the most economic and the most suitable soultion will be carefully designed to meet the customers' taste and needs.

Service in sale:

Careful preparation:Deeper communication with and fuller understanding of the customers and their needs will de achievedin such ways: Market survey, technique change, training and consultancy.

Service after sale:

A.Try our best and ensuring their satisfation

B.Achieve the best ruselts at all costs

C.Be honest, respecting the customers, new service, high economic

We always respect the customers' choices.We devote ourselves to providing satisfactory products and service at low costs., taking the extent of the customers' satisfaction as the sole standard, and so we have earned their long-term trust.

Introduction of Our Company:

SBT Plastics Technologies Co., Inc

An Enterprise specializing in the manufacture of Plastic Auxiliary.

SBT Plastic Technologies (Huizhou) Co., Inc is located in Huizhou City, in the southern Part of China. Since its inception, SBT Plastic has foucsed strongly on R&D and innovation to bring value to our clients. Our R&D efforts include developing a new injection molding of the peripheral equipment, specializing in producing drying and dehumidifying, feeding and conveying, dosing and mixing, heating and cooling, granulating and recycling, Centralize system and Automation, Six series etc. We also design series of system like, PET systems, centralize feeding system, centralize drying and dehumidifying system, centralize cooling water systems, total five systems. SBT plastics produce fully equipped systems that are highly efficient, energy saving and environmentally friendly. We are thus able to provide our clients with a one-stop solution for their plastics machinery needs.

At SBT plastic, we spend the time and effort to produce superior products just for you.

Our company is well known both at home and abroad for high quality products and complete service systems. Our products sell well all over the world.

Any information, please send messages below to us. We will give you best answer!

BTCD-9

BTCD-9  BTCD-20

BTCD-20