Strong Crusher for granulate and recycle all kinds of plastics material of different texture and shapes

BG series

Strong Crusher

General Description

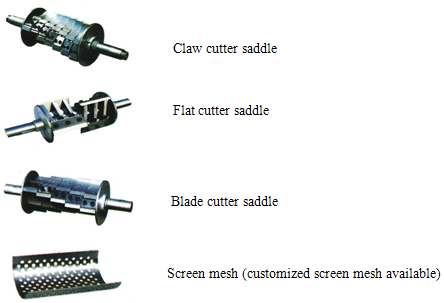

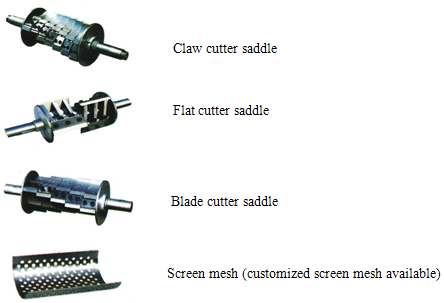

BG series of granulators include claw cutter series.flat cutter series and blade cutter series.They are applicable to a wide rang,can meet a wide variety of requirements,able to granulate & recycle all kinds of platics material of different texture and shapes.

Features

BGY Jaw crusher series:

Applicable to all kinds of plastic crushing reuse, especially for all kinds of rigid plastic (such as head, shoe materials) effect is better.

BGY series crusher has the advantages of convenient operation, simple and quick change knife; knife design optimization, claw-type blade dispersing the power, makes the angle of each blade to increase, suitable for crushing thick material, hard block, head, effectively improve the cutting force, reduced to tool wear; with electric safety design, hopper used double layer structure, filled with insulation material, the device has good security, environmental protection, energy saving and durable.

BGD Flat type crusher series:

Applicable to the box head, thin pipe, blow molding, bottle, shell and other plastic recycling.BGD series crusher has the advantages of convenient operation, simple and quick knife change, flat knife big structure suitable for crushing large volume thin, thin material products, improve the crushing efficiency; using electric safety design, hopper with double layer structure, filled with insulation materials, motor with overload protection device, a power interlock protection system, which makes the device have good safety and environmental protection, energy saving and durable.

BGP Sheet type crusher series:

Type blade structure between claw knife, knife, broken for ordinary sheet, pipe, profile, sheet and packaging materials such as plastic products, water crossing.General purpose plastic disintegrator, sealed bearing, the bearing rotation for a long time to maintain good; well designed cutter blades, uniform granule; knife blocks thermal processing, elegant appearance design.

Specifications

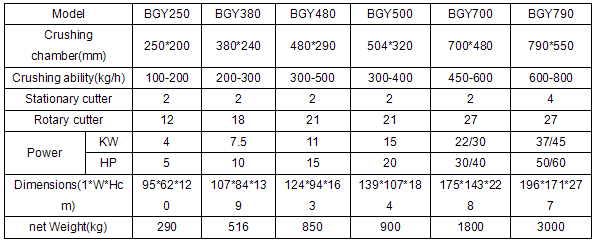

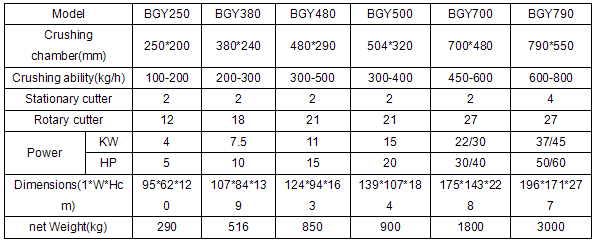

BGY SPECIFICATIONS(Claw type)

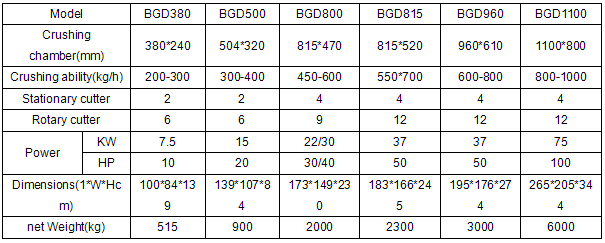

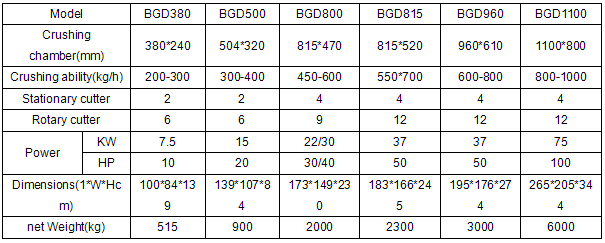

BGD SPECIFICATIONS(Flat)

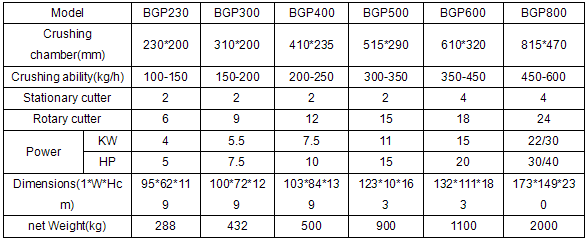

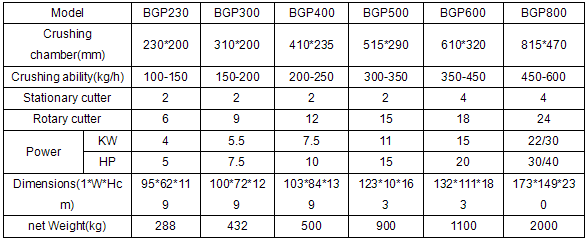

BGP SPECIFICATIONS(Chip type)

Why choose us?

1.We can make and manufacture products according to customer specific needs.

2.Provide best and professional service for you, please contact with us freely.

3.For more information, please contact us at any time.

4.Stable performance, best price, good quality, good after-sales service.

SBT - Quality First, Always

At SBT, we believe in the business philosopu of "service, quality, honesty and trust". We are grateful for the support of our clients and are committed to continuously develop innovative products to help them in their business. We firmly believe that when our clients succeed, we succeed. Our innovative efforts have seen us attained ISO 9001:2008 and the European CE certification.

At SBT Plastic, we are committed to continuously innovate and improve our products and services.

Hearty service:

1.Before sending the machine, we will test and adjust, so you can use directly when you get it.

2.Operating video & instruction will be sent to clients, to help them better use the machine.

3.Any problems occur while using, professional advice will be given by us.

4.All kinds of frequently used parts are supplied from us all the year round.

Service before sale:

Customer-oriented:Best-developed, the most economic and the most suitable soultion will be carefully designed to meet the customers' taste and needs.

Service in sale:

Careful preparation:Deeper communication with and fuller understanding of the customers and their needs will de achievedin such ways: Market survey, technique change, training and consultancy.

Service after sale:

A.Try our best and ensuring their satisfation

B.Achieve the best ruselts at all costs

C.Be honest, respecting the customers, new service, high economic

We always respect the customers' choices.We devote ourselves to providing satisfactory products and service at low costs., taking the extent of the customers' satisfaction as the sole standard, and so we have earned their long-term trust.

Introduction of Our Company:

SBT Plastics Technologies Co., Inc

An Enterprise specializing in the manufacture of Plastic Auxiliary.

SBT Plastic Technologies (Huizhou) Co., Inc is located in Huizhou City, in the southern Part of China. Since its inception, SBT Plastic has foucsed strongly on R&D and innovation to bring value to our clients. Our R&D efforts include developing a new injection molding of the peripheral equipment, specializing in producing drying and dehumidifying, feeding and conveying, dosing and mixing, heating and cooling, granulating and recycling, Centralize system and Automation, Six series etc. We also design series of system like, PET systems, centralize feeding system, centralize drying and dehumidifying system, centralize cooling water systems, total five systems. SBT plastics produce fully equipped systems that are highly efficient, energy saving and environmentally friendly. We are thus able to provide our clients with a one-stop solution for their plastics machinery needs.

At SBT plastic, we spend the time and effort to produce superior products just for you.

Our company is well known both at home and abroad for high quality products and complete service systems. Our products sell well all over the world.

Any information, please send messages below to us. We will give you best answer!