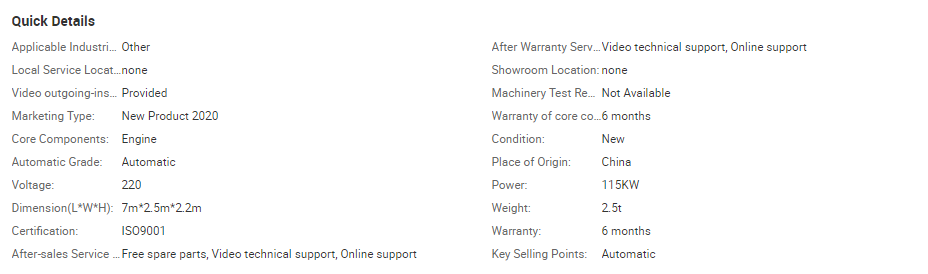

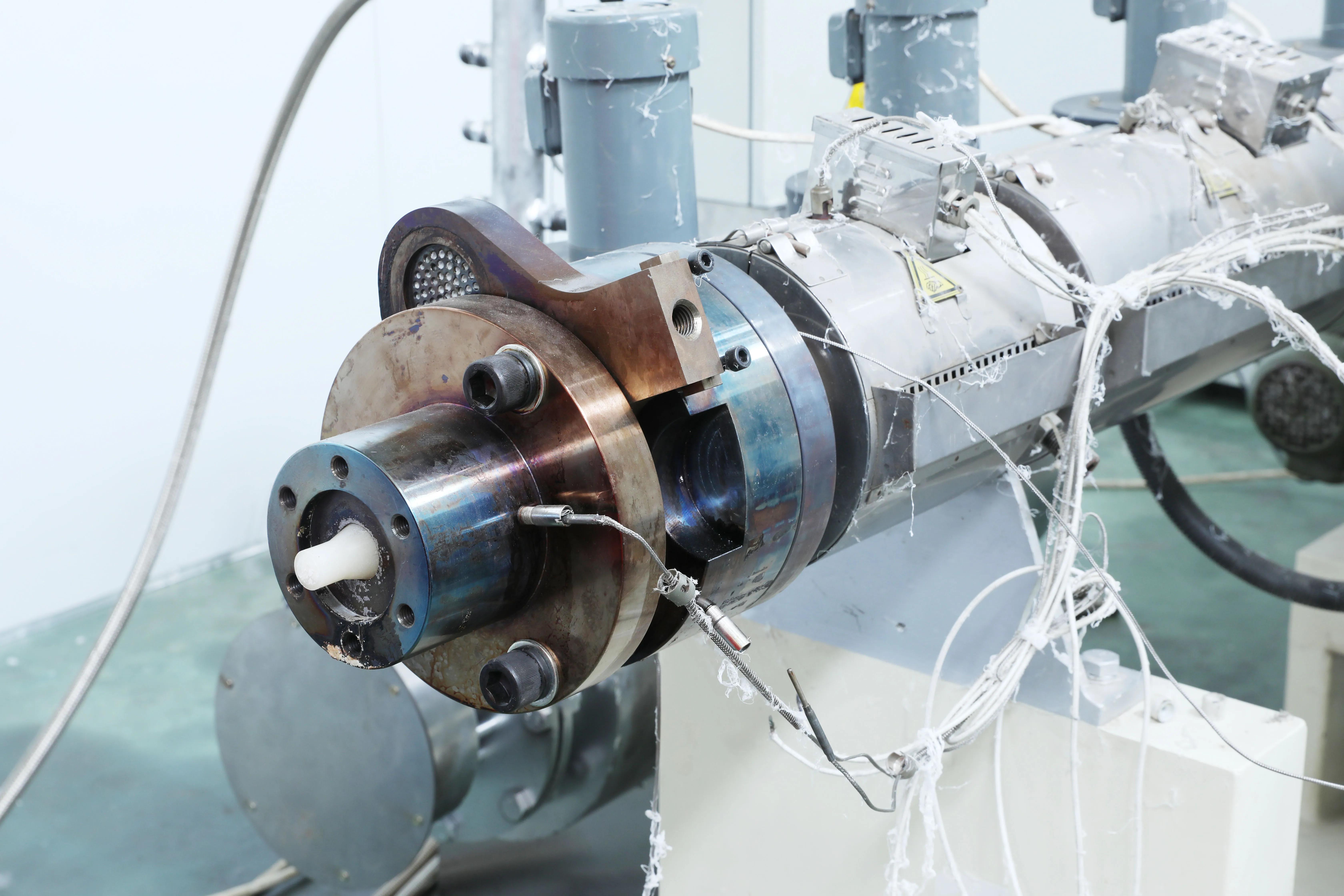

The working principle of the production line: the automatic feeding machine automatically sucks the polypropylene PP particles and sends them to the extruder. The screw extruder heats and melts the PP particles to form a high-temperature polymer melt, which is sent to the melt-blowing die through the melt filter and the metering pump , Under the action of high-temperature and high-speed airflow, the melt is sprayed to form extremely fine short fibers, and condenses onto the collection device to form a

web, which is bonded and strengthened to form a nonwoven fabric, and finally through the electret, cutting, collection And other processes produce roll-blown melt-blown cloth.

Our company provides complete solutions for N95 meltblown fabric production line. With the best product line that can meet the performance of customers, with outstanding project technical experience and excellent production team, it provides high-quality melt-blown cloth equipment and technical services in the industry.

Advantages:

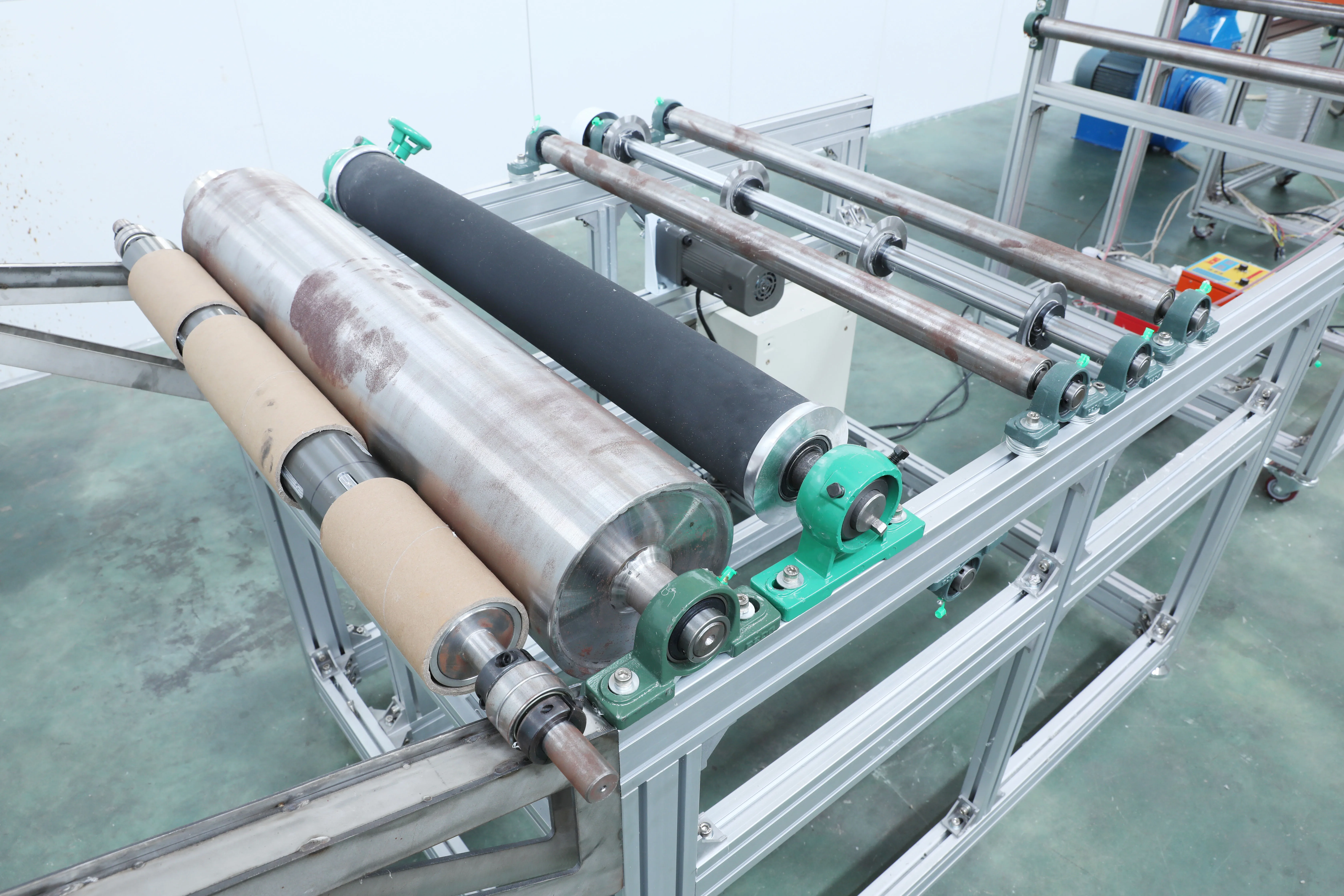

1.65-30 PP special screw machine, continuous and stable feeding;

2. High-precision metering pump, stable and uniform wire output;

3.600mm melt-blowing die head 0.2MM nozzle hole, to ensure fiber density meet N95 requirements

4. Multi-point measurement and monitoring of process conditions: ensure process stability

5.120KV high-efficiency dual-electret system: to ensure that the product filtration level reaches the N95 standard