| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

SET

TOTAL COST

$1660| Material : Default |

| Pcs/Carton : N/A | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : N/A | QTY in 20GP : N/A |

Mould sweat dehumidifiers to remove moisture sweat from condensing on mould surface

BMD Series

Mold Sweat Dehumidifiers

General Description

BMD series mould sweat dehumidifiers are designed to remove moisture sweat from condensing on mold surface. Moisture condensation on the mold surface is due to the use of chilled water for reducing molding cycle time, particularly while molding PET perform. When mold surface temperature is lower than dew-point temperature of surrounding air, the water vapor comes into being, which leads to moisture condensation, and then affect product quality and production efficiency as well as bring corrosion to the mold surface and cause environmental pollution. This series of machine uses honeycomb rotor to carry out dehumidifying fuction, which ensures the srrounding air of mold remaining in a low dew-point temperature raning from +5℃~10℃. It greatly reduce the reject ratio by making mould no moisture condensation on its surface and not affected by changes of seans.

BMD-500H

BMD-500H

Featrues

Stanard configuration

1) Adopts P.I.D temperature control system, can set regenerative temperature, and have display screen of actual temperature.

2) Honeycomb rotor is used to ensure constant air dehumidifying effect.

3) Microprocessor board is fitted to indicate machine running status and to diagnose malfunctions.

4) Motor overload and phase reverse alram fuctions are included.

5) Return air cooling and filtering are included.

6) Under normal state and atmoshperic conditions the humidity content of air can be controlled exactly all year round

7) Inhibits corrosion and prolongs service life of the mould and yet reduces moulding cycle time

8) Air temperature generated by this series of machine is about 30 degree, which ensures no moisture condensation on view of window of the molding machine by making the ambient temperature not too low.

Application

Accessory option

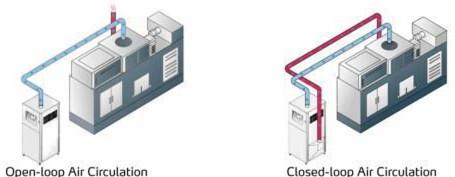

1) Returm air collector is optional a refurn air collector is used to collect return air from the moulding area back to this machine and to form a closed-loop air circulation which is particularly practical in tropical climate

2) Dew-point moitor can be fitted as option to detect ary air quality.

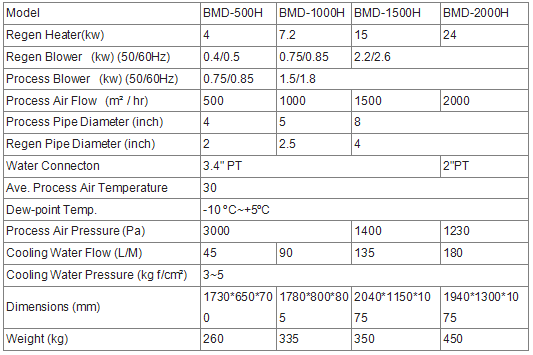

Specification

Note:

1) Noise level ≤ 85dB(A).

2) Condition for Open-loop application Ambient dry bulb temp ≤30ºC, relative moisure ≤ 70%.

3) Cooling water required temperature 7~10ºC.

4) Power 3Φ , 230/400/460/575VAC, 50/60Hz.

Allocation reference

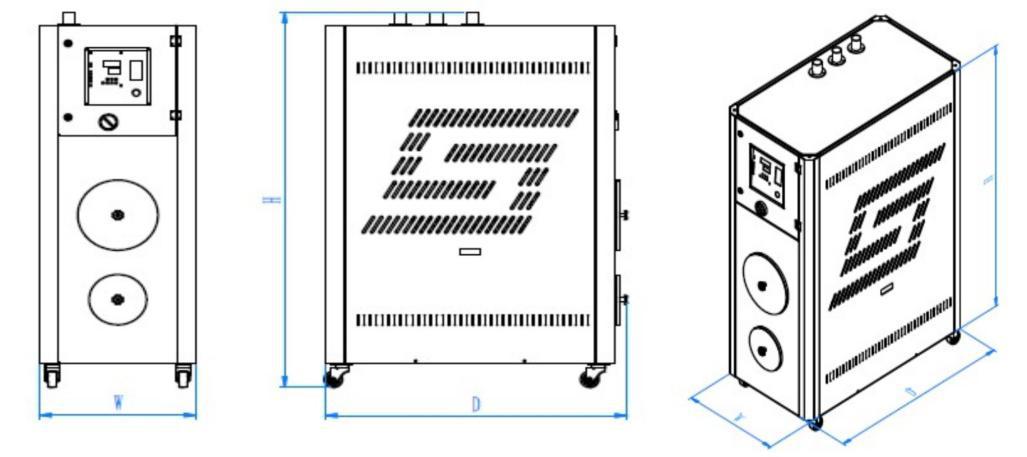

Outline drawing

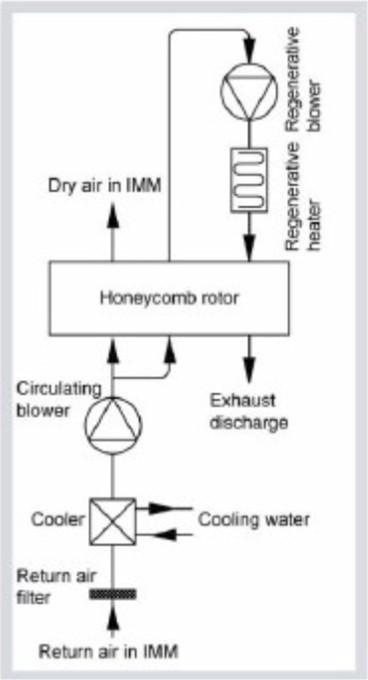

Working Principle

The large amount of air created by centrifugal blower will directly blow to the models of IMM after being moisture absorbed by rotator honeycomb to form drying air with low dew-point. And then air discharges through air outlet of mold closing chamber and returns to mold sweat dehumidifier through return air pipe. In this way, a circle finished.

The air around mould is very dry with dew-point less than or equal to 5 degree. Environmental temperature drops fast during the mould rapid-cooling, but temperature would not fall to 5 degree. Therefore, dewdrop would not come into being during mould rapid-cooling.

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.