| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

SET

TOTAL COST

$1660| Model : I | Model : I | Payment Terms : L/C, Western Union | Delivery Port : Xiamen | Product Advantages : Well and High Quality Control, Prompt Delivery, New Product, Competitive Prices, Earth-friendly Products, Small Order Acceptable, ODM Accepted, OEM Accepted, Other |

| Material : Default |

| Pcs/Carton : N/A | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : N/A | QTY in 20GP : N/A |

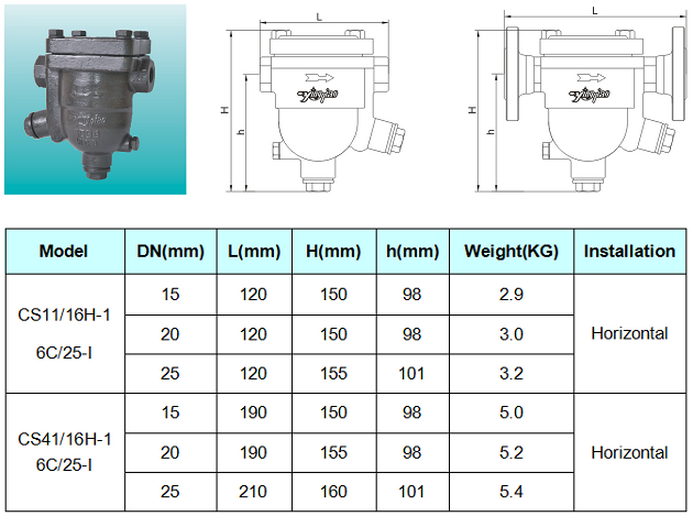

Working Principle:

Buoyancy principle is applied to this trap. The float ball rises and falls as per condensate level change, thus adjusting the openness of the valve seat hole automatically and draining condensate continuously. When condensate does not come in, the float ball falls to the bottom due to gravity and the valve seat hole closes. Because the valve seat hole locates below the condensate level, water and air are naturally separated, and water sealing forms so that no fresh steam leaks.

Performance/Advantages:

1. Able to Discharge Saturated Condensate

No water collects in the heating equipment, thus reaching higher heat exchange efficiency.

2. Not Affected by Steam Pressure Change

The float ball can automatically adjust the openness of valve seat hole and work continuously with stable performance.

3. Good Air Tightness

The stainless steel float ball is perfectly circular, highly precise and with good air tightness.

4. Good Ability to Exhaust Air

The elements in Y series can automatically exhaust non-condensing cold and hot gases, thus preventing air blocking and achieving good heating result.

5. Long Service Life

The entire surface of the float ball can be used as sealing surface and no concentrated wear will happen.

6. Small Supercooling Degree & High Rate of Allowable Back Pressure

7. Able to continuously drain condensate with steady flow. When used in condensate recovery system, it takes perfectly good effects .

Features:

1. All the stainless float balls of Yingqiao Free Float Ball Products are manufactured by advanced and high-precision grinding process.

2. The automatic air discharging device adopts the internationally advanced elements -- the 3rd generation spherical sealing elements in Y series. It is able to drain non-condensing cold and hot gases, and to resist high pressure and strong water attack. Besides, it is with sensitive and reliable actions as well as long service life.

3. Priority float ball products are manufactured with the inventive patent technology of our own company. They act reliably and are suitable in the working conditions where a great quantity of condensate should be drained.

Application:

Used in steam heating equipment, condensate recovery system and working conditions where condensate need be drained rapidly. Able to drain condensate automatically, rapidly and continuously, effectively prevent steam leakage and achieve best heating results.

Main Bases for Model Selection:

1. Condensate load (drainage volume) kg/h

2. Highest work pressure Mpa

3. Operating pressure differential Mpa

4. Trap body material and nominal pressure

5. Connecting method and size

6. Application and steam types

*Generally, the condensate load of the selected trap should be 1.5 - 2.0 times of the actual drainage volume.

Use and Maintenance:

1. Please install and maintain the trap correctly. This is the only guarantee for safe and normal operation.

2. Please confirm if the trap body material and the maximums of pressure and temperature can meet the requirements of working conditions.

3. It is a must to clean pipelines and clear sundries before installation.

4. The float ball steam trap should be installed as close to the heating equipment as possible.

5. This trap should be horizontally installed at the lowest point of the pipeline. The flow direction should be consistent with the direction marked on the trap body.

6. Slowly open the valve in front of the trap after correct installation. Raise the temperature to normal level gradually.

Table for Model, Specification and Dimension:

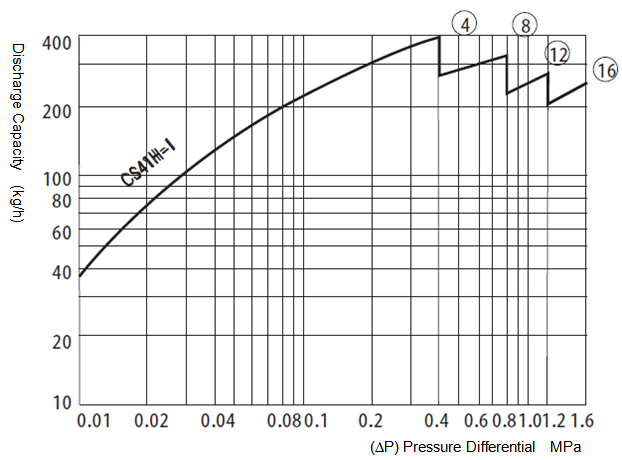

Graph for Discharge Capacity :

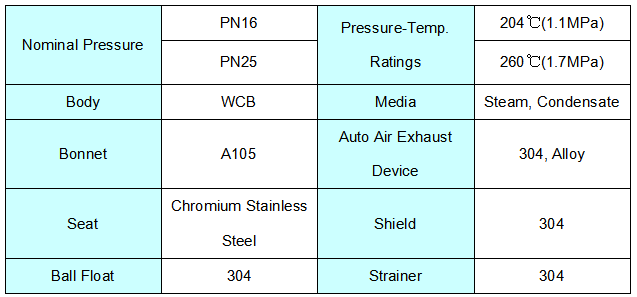

Performance Parameters/Material Table for Main Parts:

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.