| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

SET

TOTAL COST

$1660| Model : 6FYDT-200 | Payment Terms : L/C, T/T, Other | Delivery Port : tianjin shanghai | delivery Time : 30~45 days | Product Advantages : Well and High Quality Control, New Product, Competitive Prices, Earth-friendly Products, In a Variety of Design, Small Order Acceptable, ODM Accepted, OEM Accepted, Other |

| Material : Default |

| Pcs/Carton : N/A | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : 9 | QTY in 20GP : N/A |

European Standard 200 TPD large scale corn flour production line

Company introduction

Company introduction

Shijiazhuang Goldrain I/E Co., Ltd.

Mainly produce 5~1000 tons per day wheat flour production line, 5~300 tons per day corn flour production line and steel silo.

Our product obey European standard, we also have turnkey project, due to energy-saving and high-efficiency, it's a good choise for some electric-expensive countries, like Somalia.

Product Exhibition

Product Exhibition

| Photo | Name | Remark |

| Conveying system: vertical convey and horizontal convey | ||

|

Bucket elevator |

Vertical convey function: lift corn up there are different heights of elevator, select according to your workshop dimension. |

|

Screw convey |

Horizontal convey Function: convey raw corn, clean corn or corn flour |

| Cleaning system: Remove large, small, light impurities and corn bitten by insect. | ||

|

high-efficiency vibrating sieve |

There are two layers of sieve frames, upper one and lower one remove largesize and smallsize impurities seperately, connected blower to blow away light impurities.

|

|

Gravity classifier destoner |

There are also two layers of sieve frames, under fuction of frame shaking and airflow, stone and raw corn moves to opposite directions. |

|

Washer |

Use water to wash raw corn, also filter out heavy impurities, like stone and sand. There is one disadvantage: waste water and produce pollution, so this machine can be omitted, depend on customer demand. |

|

Dampener |

Computer-controlled, spray water to material make it wet to increase the tenasity of skin. |

|

Magnetic seperator |

There are magnets inside of cylinder, remove iron ore, iron chips, avoid damage to the following machine. |

|

Corn crusher | Peel corn skin, crush cron into small sizes. |

| Milling system: mill corn into corn flour, corn grit, corn embryo, bran | ||

|

Penumatic mill |

Several motors support the operation of mill, there are different types of roller for your choose according to final product you need. |

|

Embryo selector | It can be used to select corn embryo to make corn oil. |

|

High plansifter |

There are 4 (6 or 8) silos in this sifter, with higher efficiency and better classification. |

|

Purifier |

Classify material out from mill, different bulk will enter into different system. connected blower will collect corn flour. |

| Packing system: manual packing and automatic packing is available | ||

|

Auto-packing machine |

There are two types for your option, one for 10~25kg and the other for 25~50kg. |

Machinery parameter

Machinery parameter

| Name | 200 TPD corn flour production line |

| Brand | Goldrain |

| Type | 6FYDT-200 |

| Capacity | 200~250 tons per 24h |

| Raw material | corn maize |

| Final product | corn flour, corn grit, corm embryo, bran |

| Voltage | 220/380V |

| Frequency | 50HZ |

| Total power | 480KW |

| Working flow | cleaning milling packing |

| Certification | CE ISO BV |

| Service | 24-hour online, oversea installation, commisioning and training your workers |

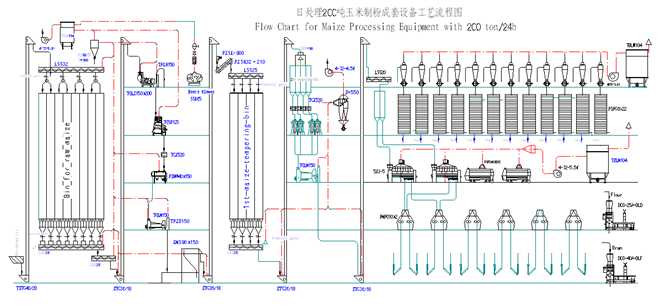

Flow chart

Flow chart

(200 TPD corn flour production line)

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.