| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

SET

TOTAL COST

$1660| Model : BHD-50T | Payment Terms : L/C, T/T, Western Union | Delivery Port : Guangzhou/Shenzhen | delivery Time : 15 days for ready goods | Product Advantages : Well and High Quality Control, Prompt Delivery, New Product, Competitive Prices, Earth-friendly Products, Small Order Acceptable, OEM Accepted |

| Material : Default |

| Pcs/Carton : 1 | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : N/A | QTY in 20GP : N/A |

Effective and low cost method hopper dryer for plastic material drying during packaging,transportation and recycling, directly mounted on the moulding machine for quick drying and space saving

BHD Series

Standard Type Hopper Dryers

General Description

BHD series hopper dryers offer an effective and low-cost method for plastic material drying .Hot air is used to dry wet material drying. Hot air is used to dry wet matarials due to moisture absorption during packaging,transportation,and recycling.They can be directly mounted on the moulding machine for quick drying and space saving .For this series,hot air blows evently from botton to the top (both BHD-800 and BHD-1000 have down -blowing air pipe and accessible door for easy material clearance) of the hopper with capacity ranging from 12kg to 1000kg .all models can be supplied with optional 24hours auto start/stop timer.

BHD-50T

BHD-50T

BHD-50

BHD-50

Features

1) Adopt hot air diffuser to gain an even hot air flow to improve drying efficiency.

2) Unique hot air inlet elbow design can prevent dust piling up at bottom of the pipe heaters so to avoid buring.

3) All material contact surfaces are made of stainless steel to eliminate material contamination.

4) Separable hopper base provides easy access to hopper tank for the convenience of material changing and cleaning.

5) Proportional deviation indicative temperature controller for accurate temperature control.

6) Overheat protector to prevent accidents by human error or mechanical faults.

7) Overheat indicating light, motor contactor and overload relay are equipped standard.

8) Quick cooling blower and outfitted power switch.

9) Preheat timer and double insulated hopper are available as options.

10) More optional accessories: "L"or "A" type floor stand, Dried-material suction box, hopper magnet, magnetic base, hot air recycler, blower inlet filter, exhaust air filters, and cyclone dust separator.

Accessories Option

Cyclone Dust Separators

Effective filters 90% dust-contain air which is discharge from dryer so to avoid air pollution.

Exhaust Air Filters

Effective filters 80% dust-contain air which is discharge from dryer so to avoid air pollution.

Hot Air Recycle

Work with hopper dryer to make the hot air from a semi-hermetic circulated loop and has features as follows.

1) Hot air recycling and circulating so to avoid indoor temperature rise up.

2) Keep air in factory clean and ensure good product quality.

3) Heating by fast hot air circulation can low down energy consumption to 40%.

Magnetic Bases

Made of aluminum with built-in hopper magnet, can effectively separate metal scraps out, so to avoid material contamination.

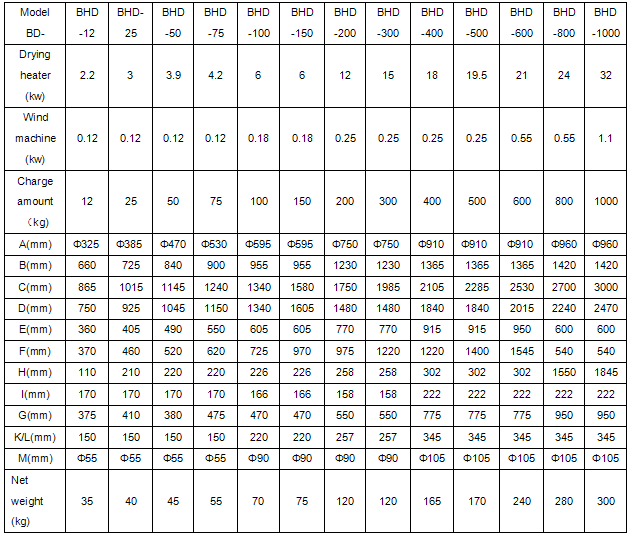

Specifications

Note: 1) Install 24HR timer, plus “T” at the back of the model.

2) Additional note of “M” will be added to BHD-300 and below models,

the bases of which are changed to be magnetic based.

3) Change into double insulated layer, add “I” at the back of the model.

4) Change into 180℃ high temp. and “H” at the back of the model.

5) Additional note single-phased voltage (free modification for BHD-75

and model below).

6) Over loading is based on the ratio of about 0.65, the diameter of 3-5mm

plastic raw material granules for standard;

7)Machine specification: 3Φ, 400V, 50Hz

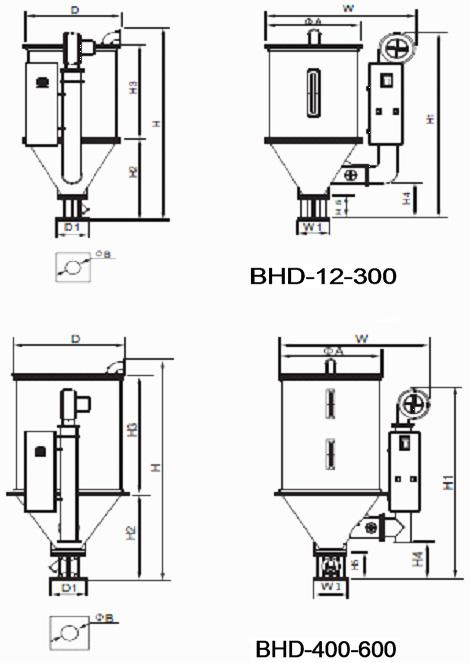

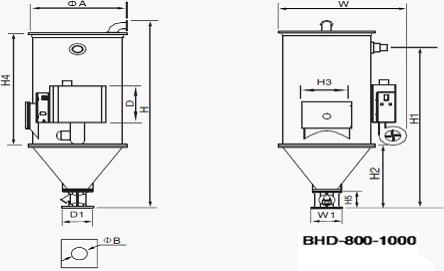

Outline Drawing

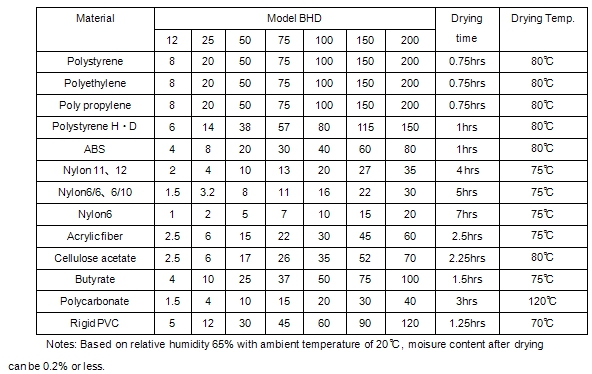

The Dryer Specification

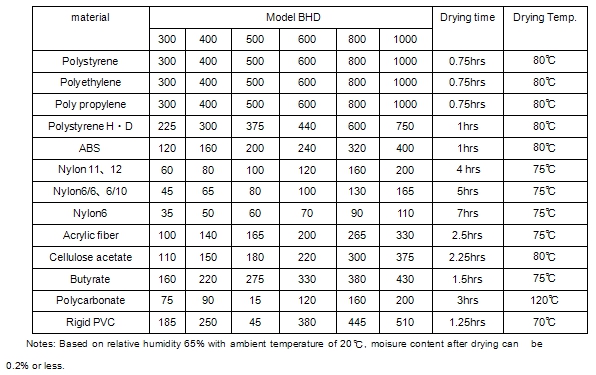

Dryer drying capacity (kg/hr) (Selection Guide)

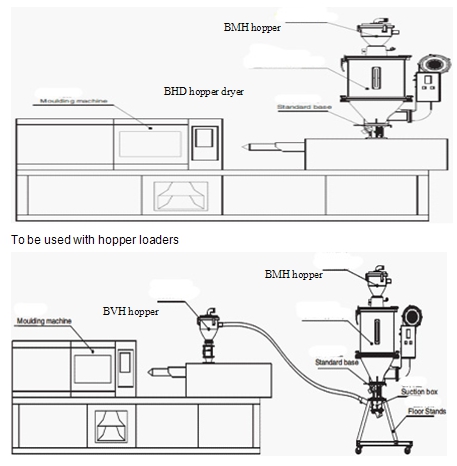

Installation

According to the installation diameter of the hoppers opening on the plastic injecting machine, drill the hole at the bottom base of the dryer, and place it vertically on the opening and fix it by tightening the screws.

Notes: When drilling, the holes diameter is the installation diameter of the hopper’s opening on the plastic injecting machine and must tighten with the screws before use.

Install directly on a molding machine

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.