| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

SET

TOTAL COST

$1660| Model : BDD | Delivery Port : Guangzhou / Shenzhen | delivery Time : 15days for ready goods | Product Advantages : Well and High Quality Control, Prompt Delivery, New Product, Competitive Prices, Earth-friendly Products, Small Order Acceptable, OEM Accepted |

| Material : Default |

| Pcs/Carton : 1 | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : N/A | QTY in 20GP : N/A |

Dehumidifying dryers combine dehumidifying and drying systems into a single unit apply in processing plastic materials, such as PA,PC,PBT,PET,etc.

BDD Series

"2 IN 1" Dehumidifying Dryers

General Description

BDD series dehumidifying dryers combine dehumidifying and drying systems into a single unit. They have many application in processing plastic materials, such as PA, Pc, PBT, PET etc. All models feature BD H series honeycomb dehumidifiers with built in process heater and insulated drying hopper which is with air down blowing design and stainless steel material. Under ideal conditions, it can provide dehumidified dry air with a dew point down to -40℃ and -50℃ with two tyoes of honeycomb rotors H4 and H5 models.

Features

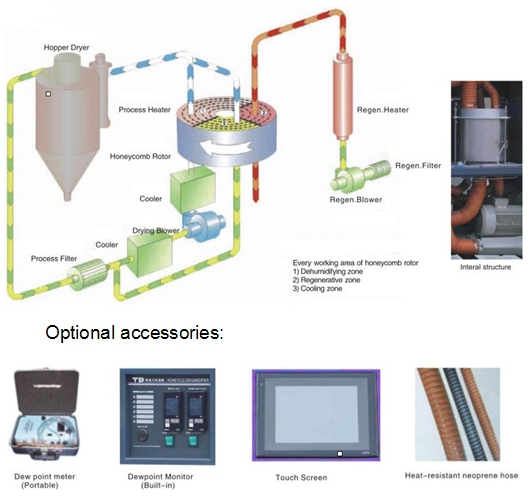

1) The BDD dehumidifying dryers use honeycomb dehumidifiers with an eye-catching semi-integral appearance.

2) Each model combines dehumidifying and drying functions into a single unit.

3) Insulated drying hopper features dry air down blowing and cyclone exhaust design. This improves drying efficiency and reduces energy consumption while maintain a steady drying effect.

4) The dehumidifying section of the BDD series features two condensers to ensure a low return air temperature and low dew-point.

5) Compact in size for ease of movement and space saving.

6) Material processing is controlled via microprocessor as standard, with PLC touch screen control as an option for more convenient control.

7) Dewpoint monitor can be fitted to check dry air dewpoint.

8) Optional suction box and hopper loader for added convenience when conveying material.

9) Upon request, it can be built to comply with worldwide electrical safety standards (For example: CE,UL,CSA,JIS etc.).

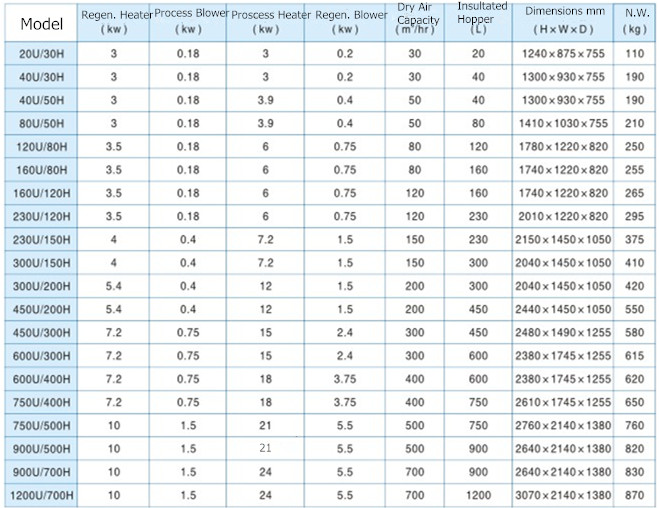

Specifications

Working Principle

In the process of material treating, BDD demoisture and drying group integrates drying and demoisture functions into on unit, mainly used for drying the plastics with strong hygroscopic characters, such as PA,PC, PBT, PET, etc. Its basic principle is to blow out the hot and moisture air from the dry hopper drum. After filtering and cooling the hot air, blow it into the honey comb rotation wheel. The moisture contained in the air will be absorbed by the rotation wheel, hereafter, will be deabsorbed by the regenerated heating air. The two air streams work together in the rotation wheel. With the rotation of the wheel, the moisture will be absorbed and deabsorbed by the regenerated air to drain out continuously, and to form a steady low dew point air. After that , heat this air until it reaches the dry temperature of plastics, blow it into dry hopper drum to form a closed loop to short the drying time and improve drying efficiency.

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.