| QTY |

| FOB PRICE |

CIF PRICE

QUANTITY

-

+

SET

TOTAL COST

$1660| Model : 6FTF-100 | Payment Terms : L/C, T/T, Other | Delivery Port : shanghai | delivery Time : 35 days after receiving paymen | Product Advantages : Well and High Quality Control, Prompt Delivery, New Product, Competitive Prices, In a Variety of Design, Small Order Acceptable, ODM Accepted, OEM Accepted, Other |

| Material : Default |

| Pcs/Carton : N/A | Packing Size/Carton : N/A | Packing Vol/Carton : N/A |

| N.W./Carton : N/A | G.W./Carton : N/A | QTY in 40HQ : N/A |

| QTY in 40GP : 5 | QTY in 20GP : N/A |

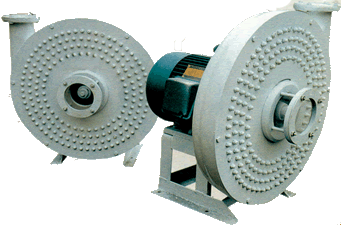

100TPD Industrial wheat flour processing machine

Company information

Shijiazhuang Goldrain I/E Co., Ltd. is a manufacturer of wheat flour processing machine and corn flour processing machine. has a experience of 6 years.

Our main products : wheat flour mill, maize flour mill, silo.

We have opened market in Algeria, Angola, Botswana, Burundi, Congo, Egypt, Ethiopia, Gambia, Kenya, Libya, Mozambique, Uganda, Zambia, Zimbabwe etc.

Successful Project

| 2010 | Ghana | 100t/24h corn flour mill machine |

| 2011 | Brazil | 50t/24h roller wheat flour mill line |

| 2011 | Philippines | 30t/d roller wheat flour mill |

| 2012 | Zambia | 20t/24h corn mill plant |

| 2013 | Philippines | 200t/d wheat flour milling machine |

| 2014 | Zambia | 30t/d Corn mill |

| 2015 | Congo | 100t/d maize meal mill |

| 2015 | Tanzania | 50t/d maize roller mill |

| 2015 | Congo | 30t/d maize milling machine |

Working process

| Cleaning |

|

|

Auto-vibrating sieve: Remove large and small impurities from raw wheat material. Wheat scourer: under the pat and friction force, impurities on surface of wheat will be cleaned off. Magnetic seperator: magnetic impurities is removed when passing through this device. Destoner: impurities with large specific gravity, like stone or sand, will be removed, also blow away light impurities. Washer: wash raw material with water to clean off the attached impurities. |

| Milling |

|

|

Mill: mill material into small sizes, separate material skin and albumen. High square sifter: there are 4, 6 or 8 silos in each device, used for classifing different sizes material. Purifier: purify material out from mill, classify these material and convey to different system. Detacher: break the flour piece up, smash into powder-shaped flour. Bran brusher: brush the flour from bran to improve flour extraction rate. |

| Packing |

|

|

Manual scale and sewing machine: for less than 10kg per bag. Auto-packing machine: two types: 10~25kg and 25~50kg. |

(wheat flour processing flow)

Process type and Basic Parameters

| Parameters | Wet method | Dry method |

| Technical for cleaning system |

Three sieves,two beating,one removing stone, two magnetic selecting, one washer

|

Three sieves,two beating, two removing stone, two magnetic selecting, one moisture dampener

|

| Technical for milling system |

Ten Milling, three Sixbin square sifter, two Purifier and two Bran finishers. |

same as wet method |

| Technical for packing system |

Three Auto-weight & packing scale |

same as wet method |

| Capacity | 100 tons per 24 hours | same as wet method |

| Voltage | 220/380V | same as wet method |

| Total power | 375kw per 24h | 365kw per 24h |

| Extraction |

grade 1 flour: 70~72% grade 2 flour: 72~75% standard flour: 75~82% |

same as wet method |

| Feature |

Advantage: wheat is washed to be clean and wheat moisture is increased. Disadvantage: waste water and produce pollution. |

Advantage: save water Disadvantage: wheat is not clean as wet method and flour quality (whiteness) is not good as wet method. |

• Amanbo Return Policy applies to all orders on amanbo.com.

• If products are not as described, returns are accepted and return shipping fee should be paid by buyer.

• If products are as described, seller has the right to refuse return. Buyer should pay return shipping fee if return require is insisted on.